Last month, the Building Owners Management Association (BOMA) of New York hosted their first off-site Brunch N’ Learn at One World Trade Center, highlighting the latest technology in vertical transportation from ThyssenKrupp Elevator. Electronic Drives and Controls, Inc. (EDC) has been a BOMA, NY member for 11 years. EDC’s Deborah Deluca, Vice President, serves as a volunteer on the professional development committee of BOMA NY. She coined the idea for Brunch N’ Learns, otherwise known as Lunch N’ Learns, back in the summer of 2016 in an effort to increase interest in the organization’s membership program. Since then, Deb has been deeply involved in the planning and production of these monthly events for BOMA members.

Last month, the Building Owners Management Association (BOMA) of New York hosted their first off-site Brunch N’ Learn at One World Trade Center, highlighting the latest technology in vertical transportation from ThyssenKrupp Elevator. Electronic Drives and Controls, Inc. (EDC) has been a BOMA, NY member for 11 years. EDC’s Deborah Deluca, Vice President, serves as a volunteer on the professional development committee of BOMA NY. She coined the idea for Brunch N’ Learns, otherwise known as Lunch N’ Learns, back in the summer of 2016 in an effort to increase interest in the organization’s membership program. Since then, Deb has been deeply involved in the planning and production of these monthly events for BOMA members.

Deb reflects on the success of this month’s Brunch N’ Learn, mentioning that “One World Trade Center (OWTC) was a special location for BOMA members to visit as it has both the fastest elevators and is the tallest building in the Western Hemisphere.” At 104 floors tall and 2.6 million square feet, the building has 71 elevators that reach speeds of up to 23 MPH- 2,000 feet per minute. “Twenty BOMA NY members including property managers and commercial real estate representatives joined us to learn more about this very impressive building and what’s new in vertical transportation.”

Joe Cossentino, Director of Vertical Transportation for Syska Henessy Group Inc., opened the event, giving BOMA members a glimpse into the history of the World Trade Center site since its humble beginnings, hosting a 22-story railroad terminal in the 1900s. Today, OWTC stands tall on the site as a symbol of hope and perseverance for New York after the tragedies of 9/11.

Joe Cossentino, Director of Vertical Transportation for Syska Henessy Group Inc., opened the event, giving BOMA members a glimpse into the history of the World Trade Center site since its humble beginnings, hosting a 22-story railroad terminal in the 1900s. Today, OWTC stands tall on the site as a symbol of hope and perseverance for New York after the tragedies of 9/11.

Joe mentions that this presentation was particularly special for him as he was a project manager of mechanical engineering, overseeing the design of 30 elevators and 50 escalators, during the rebuilding of OWTC from 2004-2013. He says, “It was a privilege to be part of the design engineering and rebuilding of the World Trade Center Site in New York City. From the day that I witnessed the tragedy on 9/11 from midtown Manhattan, to the day that I stood on the 104th Floor of One World Trade Center as they poured the final concrete slab, our sense of respect and reverence for the families and first responders, along with our sense of accomplishment and renewal by the entire design team, was part of our shared experience.”

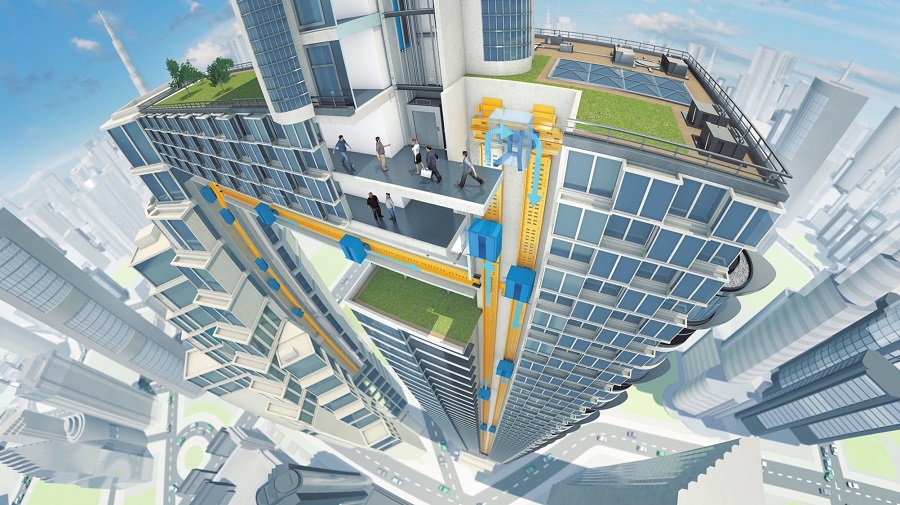

Jeffery Smith, Director of New Installation Sales in New York for ThyssenKrupp Elevators, then took the stage to deliver an innovative presentation on the future of elevators and building technology. Kenny Peng, an Account Manager for ThyssenKrupp discusses the presentation mentioning, “Attendees were given an inside look at how our new elevator systems are going to revolutionize tall building construction not just in New York, but around the world. One example of this is our groundbreaking rope-free elevator system called MULTI. MULTI elevators allow passengers to travel horizontally and diagonally in addition to classic vertical transportation. The elevators operate in a manner that compares to that of a subway, where multiple elevators run independently but within the same hoistway. This was of high interest to attendees as it is a completely new concept for elevator technology and the first building to incorporate this kind of elevator system is currently being built in Germany.”

Jeffery Smith, Director of New Installation Sales in New York for ThyssenKrupp Elevators, then took the stage to deliver an innovative presentation on the future of elevators and building technology. Kenny Peng, an Account Manager for ThyssenKrupp discusses the presentation mentioning, “Attendees were given an inside look at how our new elevator systems are going to revolutionize tall building construction not just in New York, but around the world. One example of this is our groundbreaking rope-free elevator system called MULTI. MULTI elevators allow passengers to travel horizontally and diagonally in addition to classic vertical transportation. The elevators operate in a manner that compares to that of a subway, where multiple elevators run independently but within the same hoistway. This was of high interest to attendees as it is a completely new concept for elevator technology and the first building to incorporate this kind of elevator system is currently being built in Germany.”

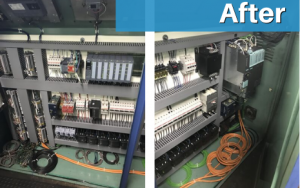

After boggling minds with elevators that go multiple directions and at lightning speeds, attendees toured one of the elevator machine rooms, where 6 of the building’s 71 elevators are located. Deb notes, “This part of the event was a great opportunity for attendees to have firsthand interaction with ThyssenKrupp Elevator technology.” The floor was then opened for networking and questions for the speakers.

After boggling minds with elevators that go multiple directions and at lightning speeds, attendees toured one of the elevator machine rooms, where 6 of the building’s 71 elevators are located. Deb notes, “This part of the event was a great opportunity for attendees to have firsthand interaction with ThyssenKrupp Elevator technology.” The floor was then opened for networking and questions for the speakers.

The BOMA NY/ThyssenKrupp Brunch N’ Learn was a great success. “BOMA members left the Brunch N’ Learn with a deeper breadth of knowledge on up-and-coming technological advances in vertical transportation with a behind-the-scenes look at one of the most impressive buildings in the world,” said Deb.

Are you a BOMA member? Stay connected with BOMA NY’s event calendar to catch your next opportunity to attend one of BOMA’s monthly Lunch N’ Learns!

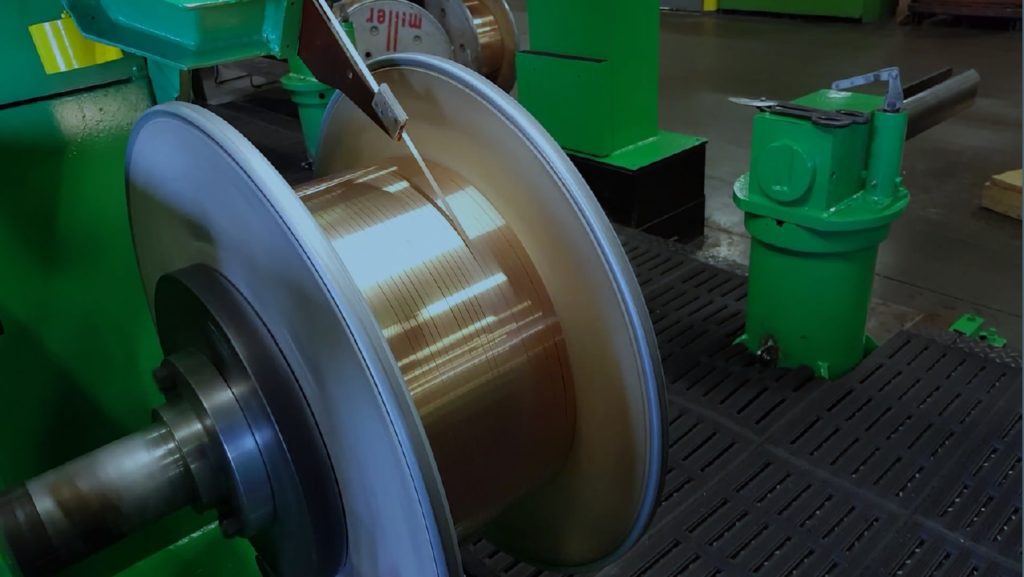

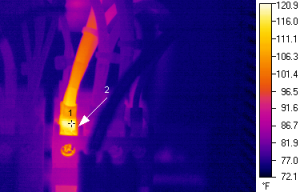

In the continuous-resistance annealing process, the secondary of the step-down transformer is connected to the wire through a rotating sheave. The voltage potential and the low resistance of the wire cause a high current to flow through the wire, heating it up. If the wire was not passing over the sheave at a high speed, it would melt. The root mean square (RMS) power level has to increase with speed. Too little power results in hard wire and too much can burn, discolor or melt the wire. EDC has mastered the control of the annealing process solving mathematical equations in real time to provide repeatability of a quality product. EDC is able to provide a constant anneal from near zero speed to full speed and back to zero at varying line speeds resulting in a predictable, flexible, and more resilient product for secondary processes and final sale to the customer.

In the continuous-resistance annealing process, the secondary of the step-down transformer is connected to the wire through a rotating sheave. The voltage potential and the low resistance of the wire cause a high current to flow through the wire, heating it up. If the wire was not passing over the sheave at a high speed, it would melt. The root mean square (RMS) power level has to increase with speed. Too little power results in hard wire and too much can burn, discolor or melt the wire. EDC has mastered the control of the annealing process solving mathematical equations in real time to provide repeatability of a quality product. EDC is able to provide a constant anneal from near zero speed to full speed and back to zero at varying line speeds resulting in a predictable, flexible, and more resilient product for secondary processes and final sale to the customer.

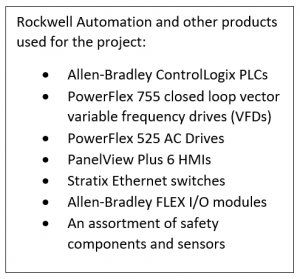

nearly 3 decades ago. As the company grew its product line and volume, its founding passion for creating delicious, top-quality chips remained the highest priority. Top-quality demands high standards. With aging equipment in its plant, the company was struggling with a rising waste percentage resulting in lost revenue.

nearly 3 decades ago. As the company grew its product line and volume, its founding passion for creating delicious, top-quality chips remained the highest priority. Top-quality demands high standards. With aging equipment in its plant, the company was struggling with a rising waste percentage resulting in lost revenue. d nearly 3 decades ago. As the company grew its product line and volume, its founding passion for creating delicious, top-quality chips remained the highest priority. Top-quality demands high standards. With aging equipment in its plant, the company was struggling with a rising waste percentage resulting in lost revenue.

d nearly 3 decades ago. As the company grew its product line and volume, its founding passion for creating delicious, top-quality chips remained the highest priority. Top-quality demands high standards. With aging equipment in its plant, the company was struggling with a rising waste percentage resulting in lost revenue.

Control Techniques’ representative, Stan, started off the training session by highlighting the differences between the company’s now obsolete Affinity series drive and the new H300 series drive.

Control Techniques’ representative, Stan, started off the training session by highlighting the differences between the company’s now obsolete Affinity series drive and the new H300 series drive. American Legion Post 86 in Newton, NJ. The company is sponsoring hole competitions for most accurate drive, closest to the pin, and longest drive in the tournament.

American Legion Post 86 in Newton, NJ. The company is sponsoring hole competitions for most accurate drive, closest to the pin, and longest drive in the tournament.